5S and Visual Control course description:

Based activities are the key aspect in the implementation of lean. 5S is a methodology for improving efficiency and 5S is the Starting Point for ALL Improvement Activities. Kaizen is a Cross-functional, Team-based Process for Rapid Improvement. Integrating 5S with Kaizen activities would require the team to be action based and focused on physical transformation through learning by doing approach. This will overcome resistance, and instill change culture among the team members in adopting the 5S culture. This 1 day 5S and Visual Control program is designed to provide key personal to understand and experience the importance of 5S to develop the disciplined work culture and the use of Visual control system as the foundation for Lean Implementation.

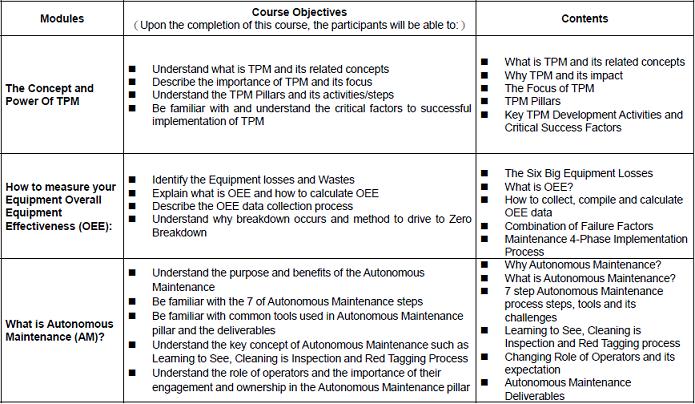

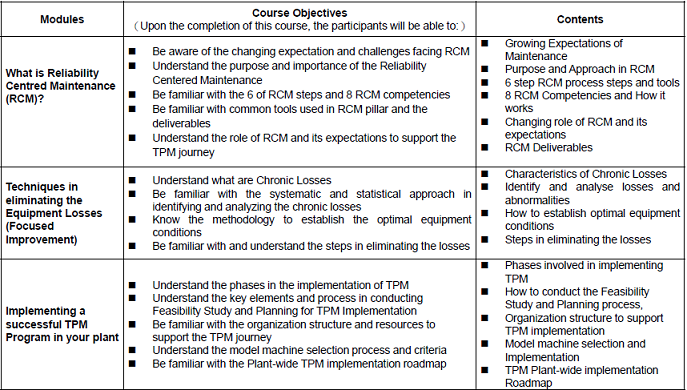

Total Productive Maintenance Course

Course Description:

TPM is a disciplined methodology developed by JIPM (Japanese Institute for Productive Maintenance) to create a culture where operators develop ownership of their equipment, and become full partners with Maintenance, Engineering and Management to assure equipment operates properly everyday. TPM is a company-wide team-based effort to build quality into equipment and to improve overall equipment effectiveness. It aims to eliminate all accidents, defects and breakdowns. Through this workshop the participants will be able to understand the fundamentals of TPM, its pillars as well as the critical success factors for successfully TPM implementation. This 2 days TPM workshop is designed to provide key personal with the knowledge of TPM; and ability to develop the structure, system and roadmap to implement TPM in their organization.